General Purpose Hydraulic Cylinders

High pressure general purpose hydraulic cylinders are available in hundreds of different configurations covering a broad range of force capacities, stroke lengths or size restrictions. Single acting, hollow plunger, or low height. Whatever the industrial application: lifting, pushing or pulling, you can be sure that Enerpac has the hydraulic jack to suit your high force application.

All Products

Viewing 1-12 of 92

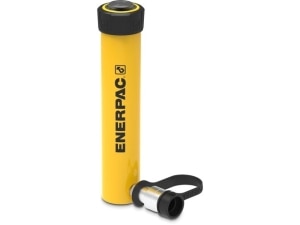

RC50

RC50, 45 kN Capacity, 16 mm Stroke, General Purpose Hydraulic Cylinder

General Purpose Cylinder

€394.00

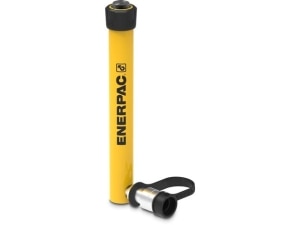

RC51

RC51, 45 kN Capacity, 25 mm Stroke, General Purpose Hydraulic Cylinder

General Purpose Cylinder

€442.00

RC53

RC53, 45 kN Capacity, 79 mm Stroke, General Purpose Hydraulic Cylinder

General Purpose Cylinder

€491.00

RC55

RC55, 45 kN Capacity, 127 mm Stroke, General Purpose Hydraulic Cylinder

General Purpose Cylinder

€548.00

RC57

RC57, 45 kN Capacity, 177 mm Stroke, General Purpose Hydraulic Cylinder

General Purpose Cylinder

€608.00

RC59

RC59, 45 kN Capacity, 232 mm Stroke, General Purpose Hydraulic Cylinder

General Purpose Cylinder

€674.00

RC101

RC101, 101 kN Capacity, 26 mm Stroke, General Purpose Hydraulic Cylinder

General Purpose Cylinder

€467.00

RC102

RC102, 101 kN Capacity, 54 mm Stroke, General Purpose Hydraulic Cylinder

General Purpose Cylinder

€515.00

RC104

RC104, 101 kN Capacity, 105 mm Stroke, General Purpose Hydraulic Cylinder

General Purpose Cylinder

€568.00

RC106

RC106, 101 kN Capacity, 156 mm Stroke, General Purpose Hydraulic Cylinder

General Purpose Cylinder

€631.00 Viewing 1-12 of 92