Light Weight Self-Contained Tensioners (SCT) – Biach RPV Tensioning Systems

Light Weight Self-Contained Tensioners (SCT) – Biach RPV Tensioning Systems

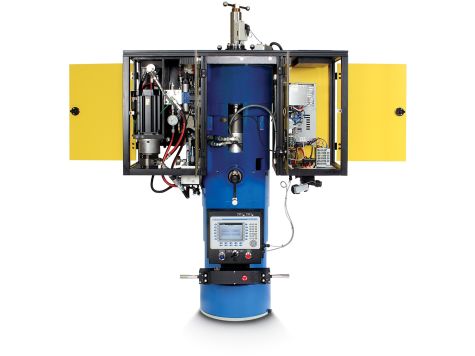

The Biach Light Weight Self Contained Tensioner (SCT) is used to tighten reactor pressure vessel head studs.

The remarkable Light Weight SCT brings greater safety, reduces manpower, lowers dose and shortens the tensioning to a critical task. Quick Latch/Un-Latch design for fast reactor pressure vessel (RPV) performance based on over 50 years of field proven use with our quick disconnect tensioners.

Power needed: 460-480VAC at 10 amps. High Speed Industrial Network Communication Protocol Communications via Cat 5 Ethernet Cable is bundled with the power distribution cable

Pressurization time: Less than 20-30 seconds per stud

Accuracy: +/- 15 psi at up to 18,000 psi maximum pressure

Weight: 3100 to 3600 lbs.

Height: Smaller than the existing quick disconnect style stud tensioners

Stud Engagement Interface:

Quick Latch/Un-Latch design for fast performance based on over 40 years of field proven use. Will engage RPV studs with a helical thread form or with an annular groove.

The Biach Light Weight Self Contained Tensioner (SCT) is used to tighten reactor pressure vessel head studs.

The remarkable Light Weight SCT brings greater safety, reduces manpower, lowers dose and shortens the tensioning to a critical task. Quick Latch/Un-Latch design for fast reactor pressure vessel (RPV) performance based on over 50 years of field proven use with our quick disconnect tensioners.

Power needed: 460-480VAC at 10 amps. High Speed Industrial Network Communication Protocol Communications via Cat 5 Ethernet Cable is bundled with the power distribution cable

Pressurization time: Less than 20-30 seconds per stud

Accuracy: +/- 15 psi at up to 18,000 psi maximum pressure

Weight: 3100 to 3600 lbs.

Height: Smaller than the existing quick disconnect style stud tensioners

Stud Engagement Interface:

Quick Latch/Un-Latch design for fast performance based on over 40 years of field proven use. Will engage RPV studs with a helical thread form or with an annular groove.

Safety Features:

- Electronic Limit Switches for:

Verifying full latch on pull system engagement to RPV stud

Checking piston overstroke travel to protect equipment components

Monitoring piston return status to prevent loss of stroke at next step - Secondary Seals to route fluid by pass to reservoir and prevent external leakage

- Text Style Instructions via an LCD screen to coordinate sequence and integrate operation

- High Pressure Safety Valve to cease high pressure operation as a secondary system to electronic overstroke limit switch in preventing piston overstroke.

- Emergency Stop button on each control panel to cease operation of all tensioners

Integrated, Built on Pumping System:

- Saves valuable refuel floor space

- Eliminates rigging of and potential leakage from interconnecting hoses (currently used)

- Reduces storage requirements

Performance Enhancements:

- Built in Elongation Monitoring System (EMS) provides instant elongation reading feedback which allows immediate re-tensioning if reading is out-of-spec and eliminates need to perform trim adjusting passes upon completion.

- Complete hydraulic operation: latching of pull system, pressurization and piston return. Does not require any air supply or create any air born contamination through air exhaust systems.

- Ram Actuators for piston return process eliminates potential of hydraulic leakage at tensioner top plate during piston return phase due to flange rotation conditions.

- System set up for one SCT to be the Master tensioner (controlling full system) with the other tensioners being secondary. At any time another unit in the system may become the Master.

Design Integrity:

- Life of Plant for major components

- High strength steel forged (vs. casting) housing component which faces repeated compression stresses

- Modular design for quick change out or for future technology replacement or upgrade

- Allen Bradley PLC controls for industry wide acceptance and reliability

Low Maintenance Costs:

- 10 year spring energized hydraulic seals reduce periodic overhaul, RWP, crew and support costs

- Elimination of current central pump (EPN) service, and periodic replacement of hoses and cables

Reduced Crew Requirements (one man per tensioner):

- Fatigue eliminated through turn-of-the-switch stud engagement

- Simple movement left or right and hoist operation up or down through built on controls

- Integrated communication system coordinates operation