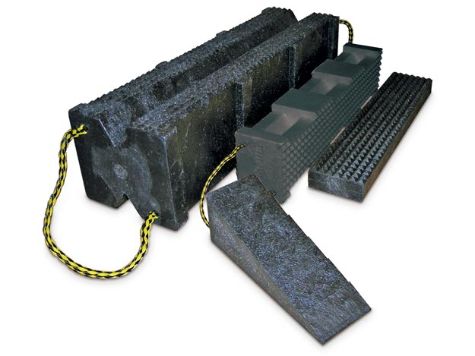

LPC2401B, 2 x 4 in Single Resin Cribbing Block, Black

LPC2401B, 2 x 4 in Single Resin Cribbing Block, Black

Model: LPC2401B | Series: LPC | Product Line: Industrial Tools

- Enerpac resin cribbing blocks are designed to provide superior crib stability compared to standard hardwood and softwood products. Enerpac resin cribbing blocks won't fail catastrophically like wooden cribbing; instead of snapping or cracking and collapsing, it gradually deforms providing a visual warning of overload. In addition, unlike wood products, Enerpac resin cribbing blocks do not splinter or absorb most fluids. Convenient sizes help to quickly and safely build stable cribs to support loads. Enerpac cribbing blocks have two distinct surfaces: interlocking and pyramid. The interlocking surface ensures block alignment at a 90 degree angle; the pyramid surface can be utilized to build crib stacks at odd angles, less than 90 degrees.

- Multiple sizes, shapes fit most applications

- Interlocking or aggressive non-slip surface

- Non-conducting plastic resists oil and most chemicals

- Does not splinter, like wood

- Operating temperature range is -40 °C to +80 °C

- Made from 100% recycled plastics

- Durable crib blocks safely support and stabilize lifted loads.

- Cribbing blocks can be nailed, screwed or sawn like wood. Piloted ignition is similar to wood.

- Crib Block Capacity Crib stack may compress up to 50 mm at 21 °C with no cracked blocks. Ratings are based on a full press load in which the load is evenly distributed across the crib stack using a 25 mm steel plate to spread the load. Do not load any localized area of a crib or cribbing block at more than 1100N/cm2 (1600 psi)

- Think Safety! Do not mix different materials in crib stacks. Stable crib stacks require blocks with similar friction, compression and deflection rates. Use wedges to stabilize crib stacks when necessary. Wedges should be similar width as crib block. Distribute load over largest possible crib stack surface area. Loads must be evenly spread over the cribbing block cribs, and pointloading must be avoided.