Electric Stud Drive Tools (ESDT) - Biach RPV Stud Tools

Electric Stud Drive Tools (ESDT) - Biach RPV Stud Tools

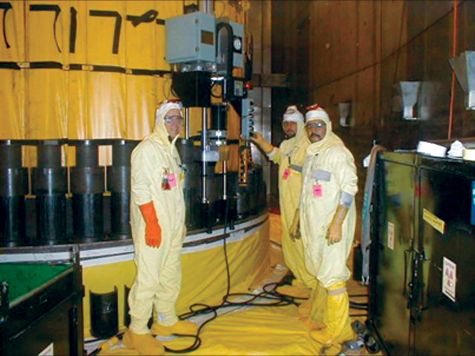

The Biach Electric Stud Drive Tool (ESDT) is used for safe removal and re-installation of reactor pressure vessel (RVP) studs in minutes.

The ESDT offers smooth, quiet operation in a noisy environment and relieves workers from the dangerous role of absorbing breakaway torque during stud rotation. Its electronic control provides an exact stud positioning during thread-in to assure consistent stud projections around the vessel and to prevent binding due to hitting the bottom of the stud hole.

Stud weight compensation is provided via a built in air compressor or by connection to plant air supply.

Enerpac's nuclear engineers converted and upgraded the earlier pneumatically driven Stud Drive Tool (SDT) to electric power.

The Biach Electric Stud Drive Tool (ESDT) is used for safe removal and re-installation of reactor pressure vessel (RVP) studs in minutes.

The ESDT offers smooth, quiet operation in a noisy environment and relieves workers from the dangerous role of absorbing breakaway torque during stud rotation. Its electronic control provides an exact stud positioning during thread-in to assure consistent stud projections around the vessel and to prevent binding due to hitting the bottom of the stud hole.

Stud weight compensation is provided via a built in air compressor or by connection to plant air supply.

Enerpac's nuclear engineers converted and upgraded the earlier pneumatically driven Stud Drive Tool (SDT) to electric power.

- Load compensation provides zero stud weight effect during operation

- Quick connect stud gripper

- Electric drive provides smooth and quiet operation

- Height of the stud during threading/unthreading is monitored and displayed on the digital read out indicator

- Safely threads studs in and out of the nuclear reactor pressure vessel (RPV) in minutes

- Easy to handle, position and operate by one person

- The operator doesn’t experience any harmful torque during stud rotation

- Pneumatic weight compensation keeps the stud ‘weightless’ during rotation which prevents any stud, stud hole or thread damage.