We have an extensive line of strong, durable hydraulic presses designed to provide long-lasting, precise and safe application of effective force in your workshop. Many presses require unique specifications, which is why our hydraulic presses can be customized to fulfill a broad range of applications. Each press is designed and manufactured according to customer specifications and in cooperation with our engineers, designers and product specialists.

We have an extensive line of strong, durable hydraulic presses designed to provide long-lasting, precise and safe application of effective force in your workshop. Many presses require unique specifications, which is why our hydraulic presses can be customized to fulfill a broad range of applications. Each press is designed and manufactured according to customer specifications and in cooperation with our engineers, designers and product specialists.

Custom Hydraulic Presses

We have an extensive line of strong, durable hydraulic presses designed to provide long-lasting, precise and safe application of effective force in your workshop. Many presses require unique specifications, which is why our hydraulic presses can be customized to fulfill a broad range of applications. Each press is designed and manufactured according to customer specifications and in cooperation with our engineers, designers and product specialists.

When you choose to work with Enerpac, we listen to your requirements and use our decades of experience in manufacturing shop presses to determine the appropriate features for your pressing needs. Whether a longer stroke, wider frame or complete new design is required, our Custom Products and Solutions team has the experience to meet the needs of virtually any industry.

Power units

- Custom air-hydraulic, electro-hydraulic power units

- Different flow rate to achieve needed advance/retract speed

- Remote Auto Cycle for Automated Operations (see controls capabilities)

- Hydraulic pressure up to 10,000 psi

Sensors

- Pressure sensors and switches

- Stroke sensors

- Load cells

- Limit switches

Hydraulic cylinders

- Double and single acting cylinders

- Tonnage: 5 - 400 tons

- Stroke: 1/4 - 80 inches

- Custom rod end

- Hydraulic pressure up to 10,000 psi

Custom controls

- Touchscreen, PLC Control, and auxiliary automation

- Digital read out of stroke, pressure and load

- User menu options (i.e. tool part numbers, specific units display, etc.)

- User entered pressure/stroke parameters

- Full control over pressure and stroke based on preset parameters

- Custom automation including loading of parts

- Automatic adjustment and movement of press using actuators

- Data output and traceability

- Output data to customer systems for display and/or traceability (data acquisition)

- Safety

- Anti-tie down buttons-requiring activation of two buttons simultaneously

- Light curtains

- Proximity Sensors

Configurations

- Vertical and horizontal press

- Cylinders mounted in upper and lower bolsters (i.e. swaging applications)

- Height built to customer specifications

- Daylight (vertical and horizontal) built to customer specifications

- Spring compression to preload shock

Commonly customizable features include

- Capacity

- Cylinder Stroke

- Pump Type

- Controls

- Guarding

- Daylight Dimensions

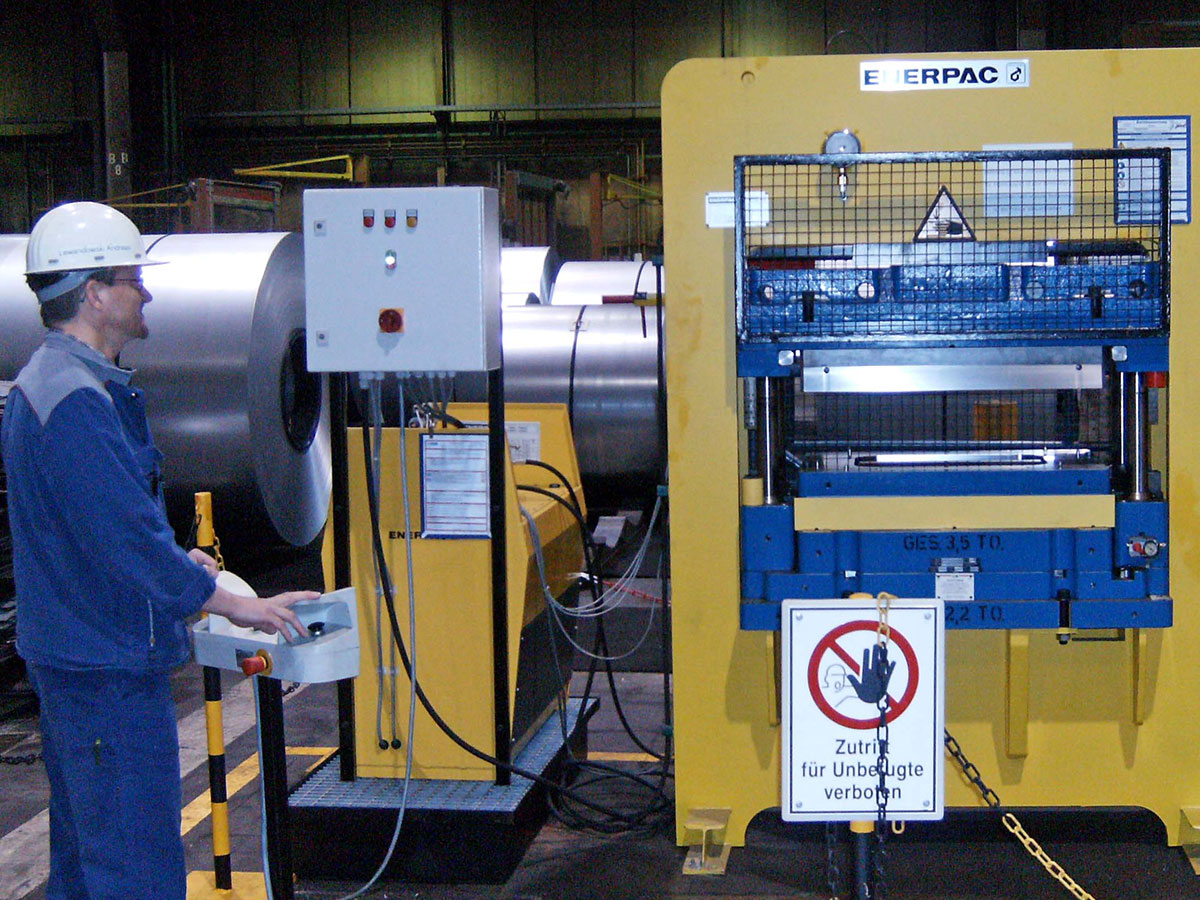

Custom Press Examples

Custom 100 ton roll frame press, with long stroke cylinder. All movements are operated and monitored through a PLC controlled pendant. The press is used for the assembly of high capacity spring loaded cylinders used for an offshore application.

Custom 200 ton deep draw press with two hand operation with a high flow pump and metal safety gate used to test the quality of steel plates.

Custom 550 ton manufacturing press for a world leading manufacturer in the automotive industry. The press is used to assemble drive train components. This semi-automated press has a daylight opening of 620 mm and cylinder stroke of 160 mm. Front and rear side feeding tables allow for easy loading of parts with a max. width of 500 mm. Steel sliding doors improve operator safety.

Custom 1,800 ton fully automated, PLC-Controlled Press. The pressing and heating cycle, during the production of magnetic acceleration coils, required high force and high- accuracy to ensure absolute quality. Control of the press force is monitored along with the temperature of the coils during forming by a PLC Control System.